Diesel engines are very powerful, but they also make some odd sounds that can confuse car owners. The characteristic diesel engine noise includes the sharp clatter of the engine at idle and the dull roar at speed. These sounds are nothing like the smooth sound of a gasoline engine, and that is because of how diesel fuel works and how it burns in the engine’s cylinders.

Unveiling the Mystery Behind Diesel Engine Noise

The main difference between diesel and gasoline engines is the answer. Many things contribute to the special diesel engine noise that diesel engines make: the way they burn fuel, the kind of fuel they burn, and their engine design.

The Basic Differences Between Diesel and Gasoline Engines

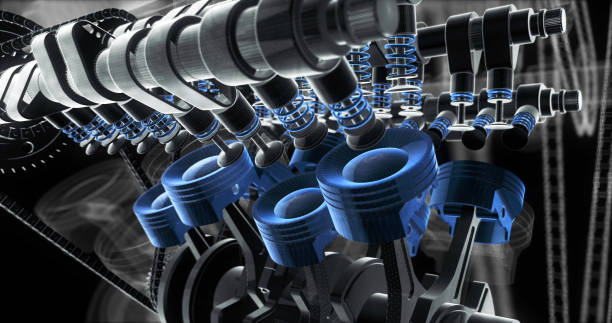

The main difference is how diesel engines create combustion. Gasoline engines use spark plugs to ignite the fuel. In contrast, diesel engines use compression ignition. They pull air into the cylinder and compress it a lot. This creates very high heat.

When diesel fuel is added to this hot, compressed air, it ignites on its own. This leads to a strong explosion that moves the piston. This method is very efficient but tends to produce more diesel engine noise than gasoline engines’ ignition process.

Because diesel engines compress more, they need stronger and heavier parts, which adds to the diesel engine noise level compared to gasoline engines.

Technical Insights into Diesel Engine Operation

To really understand diesel engine noise, we need to look at some key details of how they work. Two important things are compression ratios and fuel injection timing. These factors greatly impact the sounds we hear from these engines.

Knowing how these parts affect diesel engine noise can help us understand how diesel engines operate and why they make their unique sounds.

The Role of Compression Ratios in Noise Generation

Knowing how these parts affect engine noise can help us understand how diesel engines operate and why they make their unique sounds. Diesel engines work with much higher compression ratios than gasoline engines. This high compression helps the engine run well but also contributes to diesel engine noise. When the piston pushes air in the cylinder, it creates a lot of pressure and heat.

This quick rise in pressure and temperature can make the diesel fuel ignite too soon or unevenly. This problem is called “diesel engine knocking.” The knocking creates a sharp, metallic sound that is easy to hear, especially when the engine is under heavy loads. Diesel engine noise is particularly noticeable in these conditions.

When the compression ratio goes up, the knocking sound is usually louder, often contributing to diesel engine noise. To reduce this noise, manufacturers use different methods. They include advanced fuel injection systems and changes in engine design to help ensure smoother combustion.

How Fuel Injection Timing Influences Sound

Fuel injection timing is very important for reducing noise and improving the performance of diesel engines. This term refers to when fuel injectors release diesel fuel into the combustion chamber. The timing of this action affects how well the fuel burns and the amount of noise it makes, including diesel engine noise.

When fuel injection timing is set correctly, the fuel burns at the right time. This creates a smoother and more controlled burn, which lowers knocking noise and boosts engine efficiency.

But if the timing is off, even by a little, it can cause the engine to run rough. This can result in more knocking noise, contributing to increased diesel engine noise, and lower performance. Factors such as worn fuel injectors, a broken timing chain, or problems with the engine control unit can affect the injection timing.

External Factors Exacerbating Diesel Noise

Impact of Engine Wear and Tear

As diesel engines get older and have more miles on them, their parts start to wear out. This wear can show up in different ways. It can change how much noise the engine makes, including increased diesel engine noise. For example, if engine mounts are loose or worn, it can cause strong vibrations. This often leads to a rattling noise, especially when the engine is idling.

If the piston rings or cylinder walls are worn, it can cause blow-by. This means combustion gases escape past the piston and enter the crankcase. This can create a hissing or puffing sound.

Also, parts in the valvetrain like lifters, rocker arms, and pushrods can wear down, too. This can lead to a ticking sound that you can hear most clearly when the engine is idling or running slowly. Checking these parts regularly and replacing any that are worn is very important. This way, you can reduce the noise caused by engine wear.

The Effect of Environmental Conditions on Engine Noise

The environment a diesel engine works in can affect how loud it is, influencing the diesel engine noise. Cold weather, for example, can make the engine noisier. When a diesel engine is cold, the fuel becomes thicker. This makes it harder for the fuel to mix properly with air. As a result, the engine may not burn the fuel completely, which makes starting it noisier.

On the other hand, hot weather can change how well the cooling system works. If the engine does not get enough cooling, it can make the fan noise louder and increase the sound from the exhaust.

Other factors like humidity and high altitude can also slightly impact how well the fuel burns. This, in turn, can change how loud the diesel engine is. While these factors may not greatly change the sound, they still add to how the diesel engine is heard overall.

Mitigating Diesel Engine Noise: Strategies and Solutions

There are good ways to lower and handle diesel engine noise. Makers of diesel engines are always improving their engine designs. They are also using new technologies to cut down on noise.

Besides these improvements, good maintenance and a few simple changes can help make a diesel engine run quieter and smoother.

Advanced Noise Reduction Technologies

Modern diesel vehicles have made big improvements in reducing noise, including the reduction of diesel engine noise. One great advance is the common-rail fuel injection system. This system gives fuel more accurately and allows for multiple times fuel can be injected during each cycle. This helps make the combustion smoother and makes less noise, especially the loud clatter that old diesel engines have.

Another important change is the use of particulate filters and exhaust gas recirculation (EGR) systems. These technologies help reduce harmful emissions, and they also make the engine run quieter.

Also, builders are using better materials to make engines. They are using lightweight alloys and composites. These materials make engines lighter, which helps cut down on noise and vibration.

Maintenance Tips to Keep Your Diesel Engine Quieter

Regular maintenance is very important for managing diesel engine noise. One easy and effective step is to change the engine oil on time and use the right oil grade. Fresh and clean oil helps lubricate the moving parts well. This reduces friction and lessens diesel engine noise.

Another important task is to check and fix the timing chain if necessary. A loose or stretched timing chain can cause a rattling noise that is hard to ignore.

It’s also crucial to pay attention to any signs of engine trouble right away. A faulty lifter, worn injectors, or a failing fuel pump can increase engine noise a lot. If these problems are not fixed quickly, they can lead to bigger problems. Regular checks and timely repairs can stop small issues from turning into major diesel engine noise problems.

__________________________________________

By using advanced noise reduction methods and maintaining your engine well, you can make this noise less noticeable. Diesel engine noise can be minimized with the right strategies. If you want more tips on how to reduce diesel engine noise or have questions, please contact Phoenix Diesel Repair. Your path to a quieter diesel engine begins with smart choices and taking action.

Frequently Asked Questions

What causes diesel engine noise?

Diesel engine noise is primarily caused by the engine’s combustion process. Diesel engines use compression ignition, where air is compressed to high pressures and temperatures. When fuel is injected into the combustion chamber, it ignites spontaneously, producing a loud “clattering” sound, often referred to as “diesel knocking.”

How is diesel engine noise different from gasoline engine noise?

Diesel engines are louder than gasoline engines due to the high compression ratios they use, which create more pressure and heat. This leads to more intense combustion and the characteristic clattering sound. Gasoline engines, on the other hand, rely on spark plugs for ignition, which results in a smoother, quieter operation.

What is diesel engine knocking and how does it contribute to noise?

Diesel engine knocking occurs when the fuel ignites too early or unevenly due to the high compression in the engine. This causes a sharp, metallic knocking sound that can be especially noticeable when the engine is under heavy loads. It is one of the main sources of diesel engine noise.

Can environmental conditions affect diesel engine noise?

Yes, environmental factors like cold weather, high humidity, or high altitudes can influence how a diesel engine operates and affect the noise it produces. Cold weather, for instance, can make fuel thicker and harder to burn, leading to louder engine noise during startup.

How can I reduce diesel engine noise in my vehicle?

There are several ways to reduce diesel engine noise:

- Regular maintenance, such as oil changes and checking for worn-out components like timing chains or fuel injectors.

- Upgrading to modern technologies like common-rail fuel injection systems and exhaust gas recirculation (EGR) systems, which help improve combustion and reduce noise.

- Using lightweight engine materials and improving engine design can also help reduce vibration and noise.