Diesel engines have been around for more than a century, powering everything from cars and trucks to generators and ships. They are known for their high power density, peak torque, and fuel efficiency. However, with the increasing push for cleaner energy solutions, innovations like fuel agnostic engines are gaining attention as an alternative. While diesel engines have some drawbacks, such as high emissions of greenhouse gas (GHG), particulate matter, and nitrogen oxides, fuel agnostic engines offer the potential to reduce these pollutants and minimize their negative environmental impact, helping to protect human health.

To meet the increasingly stringent emission standards in different regions, such as EPA Tier 4 in the US, EU Stage V in Europe, and China VI in China, diesel engine manufacturers have to invest in costly after-treatment systems and complex fuel systems. These add weight, size, and maintenance requirements to the engines, reducing their performance and profitability. However, with the introduction of fuel agnostic engines, which are capable of operating on various fuels, there has been a significant increase in power density and a more compact installation envelope. This allows for increased machine capability and productivity without impacting running costs.

But what if there was a way to make diesel engines cleaner, more versatile, and more adaptable to different energy sources? What if there was a new engine platform that could run on any fuel, from diesel and biodiesel to natural gas and biogas, without compromising on power or efficiency? What if there was a fuel agnostic engine that could revolutionize the future of diesel, providing a more sustainable and flexible alternative for the industry?

That’s exactly what Cummins, one of the world’s leading engine manufacturers, has developed. The Cummins Fuel Agnostic Engine Platform is a game-changer for diesel users, especially in the off-highway sector, where applications such as haul trucks, wheel loaders, excavators, and air compressors require high power and reliability.

What is a Fuel Agnostic Engine?

A fuel agnostic engine is an engine that can run on any fuel type, without requiring any major modifications or adjustments. It can switch from one fuel to another seamlessly, depending on the availability, cost, and environmental impact of the fuel.

A fuel agnostic engine is not the same as a dual-fuel engine, which can run on two fuels, usually diesel and natural gas, but requires a separate fuel system for each fuel. A fuel-agnostic engine has a common base engine and a common fuel system that can handle any fuel.

A fuel agnostic engine is also not the same as a flex-fuel engine, which can run on a blend of gasoline and ethanol, but has a limited range of fuel ratios. A fuel agnostic engine can run on any ratio of any fuel, from 100% diesel to 100% natural gas, or anything in between.

A fuel agnostic engine is a truly universal engine, one that can adapt to any fuel scenario, anywhere in the world.

How Does a Fuel Agnostic Engine Work?

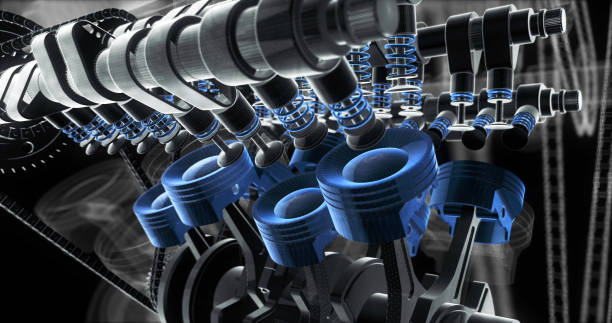

A fuel agnostic engine works by using advanced combustion technology and sophisticated control systems to optimize the engine performance for any fuel type. The engine uses a common rail fuel injection system that can deliver precise amounts of fuel at high pressures, regardless of the fuel viscosity or density. The engine also uses a variable geometry turbocharger that can adjust the airflow and boost pressure according to the fuel characteristics and engine load.

The engine has a smart electronic control unit (ECU) that can detect the fuel type and quality, and adjust the injection timing, duration, and pressure accordingly. The ECU can also monitor the engine parameters, such as temperature, pressure, and emissions, and optimize the engine operation for maximum efficiency and minimum emissions.

The engine has a modular design that allows for easy integration of different fuel types and aftertreatment systems. The engine has a common cylinder head, piston, and connecting rod for all fuel types, but has different injectors, glow plugs, and spark plugs for different fuels. The engine can also accommodate different after-treatment systems, such as diesel oxidation catalyst (DOC), diesel particulate filter (DPF), selective catalytic reduction (SCR), and three-way catalyst (TWC), depending on the fuel type and emission standards.

The engine has a clean sheet design that incorporates significant advances in engine technology, such as a sculpted block, a high-pressure fuel pump, a low-friction crankshaft, and a high-efficiency water pump. These features enable the engine to achieve higher thermal efficiency, lower weight, and a more compact installation envelope, compared to conventional diesel engines. This fuel-agnostic engine also offers maximum engine durability, making it a game-changing option for diesel users and equipment manufacturers.

What are the Benefits of a Fuel Agnostic Engine?

A fuel agnostic engine offers many benefits for diesel users, such as:

Fuel flexibility

A fuel agnostic engine can run on any fuel type, from diesel and biodiesel to natural gas and biogas, or even hydrogen and propane. This gives the user the freedom to choose the most suitable, available, and affordable fuel for their application and location. For example, a user in Nigeria can run the engine on diesel or biodiesel, while a user in Japan can run the engine on natural gas or biogas, without any major changes to the engine or the fuel system. This also reduces the dependency on a single fuel source and enhances the energy security and resilience of the user.

Environmental sustainability

A fuel agnostic engine can run on cleaner and renewable fuels, such as natural gas, biogas, hydrogen, and sustainable HVO fuel, that have lower GHG emissions and carbon footprint than diesel. This helps the user to reduce their environmental impact and meet their sustainability goals in the engine business. For example, a user in India can run the engine on renewable biogas, which has a 70% lower GHG emission than diesel, while a user in China can run the engine on hydrogen fuel cell technology, which has zero GHG emission, without any loss of power or efficiency.

This also helps the user to comply with the emission standards and regulations in different regions, such as EPA Tier 4, EU Stage V, and China VI, without requiring expensive and complex after-treatment systems. By incorporating fuel agnostic engine technology, businesses can improve their environmental sustainability and reduce their carbon footprint in the engine industry by utilizing a more diverse and greener grid of fuel options.

Performance improvement

A fuel agnostic engine can deliver the same or better performance than a conventional diesel engine, regardless of the fuel type. The engine can provide high power density, peak torque, and fuel efficiency, thanks to the advanced combustion technology and control systems. The engine can also provide longer service intervals, lower maintenance costs, and higher durability, thanks to the modular design and parts commonality.

For example, a user in the US can run the engine on natural gas, which has a higher octane rating and lower knock tendency than diesel, and achieve a 10% increase in power and a 5% increase in fuel efficiency, while a user in Europe can run the engine on advanced diesel engines using sustainable HVO fuel, also known as renewable diesel or biodiesel, and achieve a 15% increase in service interval and a 10% increase in durability.

How Can You Get a Fuel Agnostic Engine?

A fuel agnostic engine is not a distant dream, but a present reality. Cummins has already launched its Fuel-Agnostic Engine Platform, which is the first of its kind in the world. This innovative powertrain solution, also known as a fuel agnostic engine, is changing the game for diesel users by offering a versatile and environmentally friendly option for commercial transportation.

With the ability to optimize for different low-carbon fuel types, the fuel-agnostic internal combustion engine is a game-changing technology for reducing carbon emissions and promoting less environmental impact in the transportation industry.

What are the Features of Cummins’ Fuel Agnostic Engine Platform?

The platform consists of two engine families: the QSK50 and the QSK95, which cover a power range from 800 hp to 4400 hp. The engines are designed for off-highway applications, such as mining, construction, and power generation, where high power and reliability are essential.

The engines are available in different fuel configurations, such as diesel, natural gas, biogas, hydrogen, and propane, and can be customized to meet the specific needs and preferences of the user. The engines are also compatible with different emission standards and regions, such as EPA Tier 4, EU Stage V, and China VI, and can be integrated with different aftertreatment systems, such as DOC, DPF, SCR, and TWC.

For those looking for an even more advanced option, the fuel-agnostic engines, including advanced diesel engines, offer a broad power range from 450–650hp with 3,200Nm of peak torque available. Additionally, with the use of Cummins’ fuel agnostic combustion technology, these engines can also utilize sustainable HVO fuel, also known as renewable diesel or biodiesel, with ratings up to 675 hp (503 kW).

How are the Fuel-Agnostic Engines Performing in the Field?

The engines are already in operation in various sites around the world, demonstrating their fuel flexibility, environmental sustainability, and performance improvement. For example, the QSK50 diesel engine is powering a fleet of haul trucks at a copper mine in Arizona, while the QSK50 natural gas engine is powering a fleet of wheel loaders at a quarry in Germany. The QSK95 diesel engine is powering a rig at an oil field in Texas, while the QSK95 hydrogen engine is powering a generator at a power plant in California.

The engines are also being showcased at various events and exhibitions, such as CONEXPO 2023, where Cummins displayed its QSK50 natural gas engine and QSK95 hydrogen engine, and received positive feedback and interest from potential customers and partners.

If you are interested in getting a fuel-agnostic engine for your application, you can visit Cummins’ official website for more information.

Need expert diesel repairs? Contact us today to schedule your service and keep your diesel running like new!

Frequently Asked Questions

How is a fuel agnostic engine different from a dual-fuel engine?

Unlike dual-fuel engines, which require separate fuel systems for each fuel type, a fuel agnostic engine uses a common fuel system for all fuel types. It can seamlessly adjust to different fuels without compromising performance.

What fuels can a fuel agnostic engine run on?

A fuel agnostic engine can run on a wide range of fuels, including:

- Diesel

- Biodiesel

- Natural Gas

- Biogas

- Hydrogen

- Propane This flexibility allows users to choose the most cost-effective and sustainable fuel depending on their location and availability.

How does a fuel agnostic engine work?

Fuel agnostic engines use advanced combustion technology and sophisticated control systems. These systems optimize the engine’s performance based on the fuel type being used. The engine adjusts parameters like fuel injection timing and pressure for maximum efficiency and minimal emissions.

What are the benefits of using a fuel agnostic engine?

- Fuel Flexibility: The ability to use multiple fuel types offers cost savings and energy security.

- Environmental Sustainability: By using cleaner fuels like natural gas, biogas, or hydrogen, these engines help reduce greenhouse gas emissions.

- Improved Performance: Fuel agnostic engines maintain or even exceed the performance of traditional diesel engines, offering high power density, better fuel efficiency, and lower maintenance costs.

How does the Cummins Fuel Agnostic Engine Platform work?

The Cummins Fuel Agnostic Engine Platform includes two main engine families—QSK50 and QSK95—designed for off-highway applications. These engines can be customized for various fuels and emission standards, supporting diesel, natural gas, hydrogen, and propane. The engines use common parts for all fuels, with specific components like injectors tailored to each fuel type.