Diesel engine knock is the greatest fear of every diesel engine user. And that’s because the damage it causes is irrevocable. No one wants to fall into a ditch they can’t get out of. Diesel engine knocking is such a ditch. The most notable symptom of a diesel engine knock is the clanking, rattling sound that it emits. It’s okay for your diesel engine to make loud noises, but some of the noise can be signs of impending doom.

There are various measures to take to prevent your diesel engine from reaching an early demise, and we will be discussing those measures with you.

In this article, we are going to be talking about these measures, but before then let’s do a little exposition of how diesel engines work, what diesel engine knocking is all about, and what can cause it.

Let’s get started!

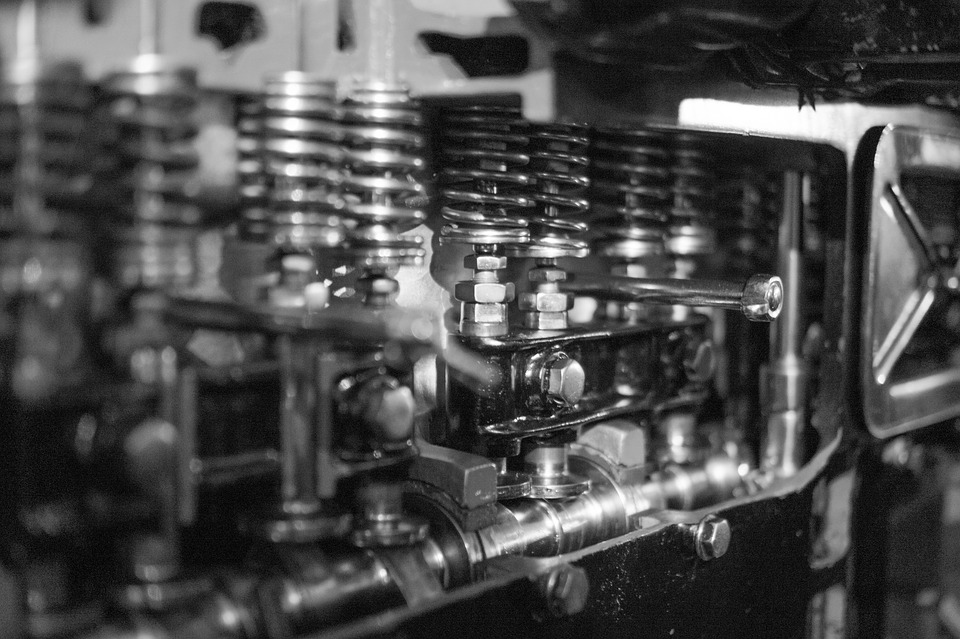

How Does Diesel Engine Work?

Let’s walk you through the working principle of your diesel engine. Knowing how your diesel engine works will set you up on the right platform to understand what engine knock, or diesel engine knocking, is all about and how it happens. This will help you stay in the know and help you make educated decisions on how to properly handle your diesel engine henceforth.

The Slider-crank mechanism

The slider crank translates the linear oscillating motion of the piston to the rotational motion of the crank. The rotational motion of the crank is what moves the wheel of your car. However, if there’s an issue like a diesel engine knocking, it can interfere with this process. For the slider crank to fully rotate 360 degrees, it needs to complete a 4-stroke cycle. Let’s talk about the four-stroke cycle.

Intake stroke

The piston starts at the very top of the cylinder and then goes downward. As it goes downward, it creates a vacuum that allows fresh air to be sucked inside the cylinder as the inlet valve opens up. Diesel engine knocking can occur if there’s an issue with the combustion process during this phase, leading to irregular engine sounds and performance.

Compression stroke

As the piston returns, it compresses the air that entered during the intake stroke. By now, the inlet valve closes and the air inside becomes compressed air. Diesel engines have a compression ratio of 14:1 to 25:1. That means 14 to 25 molecules of the air will react with 1 molecule of diesel fuel.

Power stroke

The fuel injector injects an atomized form of diesel into the cylinder. The introduction of diesel into the compressed hot air causes an explosion. This explosion pushes the piston back to the bottom of the cylinder.

Exhaust stroke

The piston bounces up back to the top of the cylinder. Thanks to the great force it used to hit the bottom. As the piston goes upward, it pushes out the exhaust the explosion of the power stroke created.

Diesel Engine Knocking

Have you ever observed disturbing sounds from your diesel engine before? That tapping or pinging sound from your engine may be because of a diesel engine knocking. Knocking occurs when the explosion happens during a stroke that is not a power stroke.

How Is That Even Possible?

During the power stroke, residual fuel can be left in the combustion chamber. This residual fuel can now further be ignited during a different stroke that is not the power stroke. The chances of diesel engine knocking increase with the increase in compression ratio. That’s because the higher the ratio, the higher the temperature inside the combustion chamber. This means hotter the air. More chances of ignition.

9 Preventive Measures to Prevent Diesel Engine Knocking

Now that you understand the cause of diesel engine knocking, let’s show you the various measures you can take to prevent that.

Case in point:

1. Take care of the engine radiator

Your vehicle radiator is what keeps the diesel engine cool by transferring heat from the engine to the outside air. The antifreeze or coolant travels through the engine picking up heat and dissipating it into the outside air.

Diesel engines run hotter than gas motors, so they subject the radiators to a higher temperature. Which means it has more work to do.

Overheating may warp the cylinders and gasket seals, which can lead to diesel engine knocking.

Proper cooling system maintenance is the best way to prevent your diesel engine from overheating, which can lead to knocking.

2. Change your fuel filters

Gas vehicles have just one fuel filter, while most diesel engines have two filters. A primary fuel filter between the engine & diesel tank, and a secondary filter which is between the pump transfer and the fuel injectors. A damaged fuel filter can cause water to mix with your diesel.

A few things could happen when there are water particles in your diesel.

Your engine may stall.

Decrease in horsepower.

Injectors could explode.

Any of these can lead to diesel engine knocking. Most diesel engines require a fuel filter replacement for every 10,000 to 15,000 miles. The older the vehicle, the more frequently you should change your fuel filter. However, we advise you to stick to your manufacturer’s recommendation for your vehicle’s make and model.

Keep this in mind: it is best to replace both primary and secondary filters at the same time to maximize their efficiency and lifespan.

3. Change your oil

Reluctant to change your oil? Get ready for the consequences. You should change the oil at least every three months if not your diesel engine will wear and tear in a short time.

Always keep the oil of your engine topped for the smooth and efficient running of your diesel engine.

4. Check the oil filter

Make sure the oil filter is always clean and free from debris to keep your engine running smoothly.

Dirty filters may lead to clogging, loss of power, or even breakdown. A clean filter is key to keeping your diesel engine sound and preventing issues like diesel engine knocking.

5. Use the right fuel

Bad fuel may damage the pump of your car or truck. Diesel engines require fuel to operate efficiently.

Using the right fuel is important if you are using a diesel vehicle that has an emission system. The wrong fuel will cause damage to your engine.

6. Flush out the old fuel

When you buy your diesel vehicle before you start using it, make sure you flush out all the old fuel. Some vehicles will run smoothly.

7. Get a diagnostic test

Before you do any repair on your diesel engine, make sure it comes with a diagnostics test so the technicians will see if there are any clogs in your filter or any other part of the system.

8. Early warning system

The system gives a warning if the engine is overheating. Prolonged overheating can cause engine knock. You should check regularly the system.

9. Check your air filter

A dirty filter will choke your diesel engine and cause it to consume more fuel to get the power required to accelerate.

If the engine power drops, or poor acceleration, your air filter may require changing. Always ensure that the air filter is clean.

Get into the maintenance habit

Going for routine maintenance should become your habit. You can start with monthly checks. If you do routine checks, your engine will last for a longer period.

We have 25 years plus of diesel service experience, contact us for your diesel maintenance and repair. Our passion is to keep your vehicle safe on the road and we offer diesel performance at the best price in town. Reach out to us.

Frequently Asked Questions

What causes diesel engine knocking?

Diesel engine knocking is caused by residual fuel igniting at the wrong time during the engine’s cycle, leading to irregular combustion. The higher the compression ratio in the diesel engine, the more likely it is to experience knocking due to increased temperatures inside the combustion chamber.

How can I prevent diesel engine knocking?

To prevent diesel engine knocking, regular maintenance is key. This includes checking and maintaining the engine radiator, changing fuel and oil filters, using the correct fuel, and flushing out old fuel. Additionally, regular diagnostics and air filter checks can help prevent issues that lead to knocking.

Can diesel engine knocking damage my vehicle?

Yes, if not addressed early, diesel engine knocking can cause severe damage to the engine, including warping cylinders and seals, which may lead to costly repairs. Regular maintenance and timely checks can help avoid such damage.

How do I know if my diesel engine is knocking?

The most obvious sign of diesel engine knocking is a clanking or rattling noise coming from your engine. This noise indicates irregular combustion, and it’s important to have it inspected immediately to avoid further damage.

What are the symptoms of diesel engine knocking?

Symptoms of diesel engine knocking include a loud clanking or pinging noise, decreased engine performance, and sometimes a loss of power or acceleration. If you notice these symptoms, it’s essential to take action before the knocking worsens.