If you’ve ever felt the frustration of a diesel that wouldn’t start, you’re not alone. Unlike gasoline engines, diesels require a very specific combination of heat, pressure, and fuel to get going. While this design brings many advantages, it also creates certain challenges starting up under particular conditions.

This invaluable guide gets into the nuances of the diesel engine starting system, describes common culprits for most starting problems, and gives ample tips for troubleshooting and preventive maintenance processes.

- Diesel motors start differently compared to gasoline ones.

- Starting problems can be expected to be more prevalent with diesels because of their nature and design dependence on compression and heat.

- The most common causes include fuel system issues, electrical problems, and low compression.

- Proper maintenance and regular care will prevent most starting problems.

- If it still doesn’t work after troubleshooting, have it looked at by a professional from Phoenix Diesel Repair.

How the System of Diesel Engine Starting Works

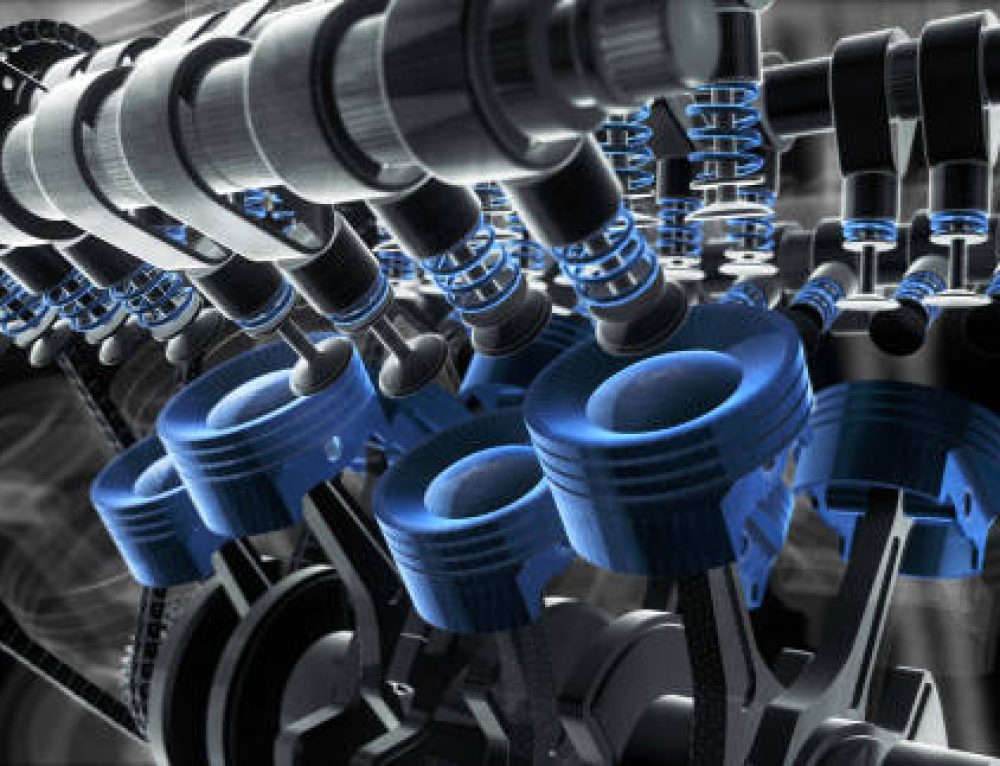

Before getting into the problems, let’s first get familiar with some key players in the diesel engine starting system:

- Glow plugs: These small heaters heat up the combustion chamber to the required temperature level so that diesel fuel ignites.

- Starter motor: A large electric motor that turns the engine crankshaft to gain the momentum to compress.

- Fuel system: It consists of a fuel tank, fuel lines, fuel filter, fuel pump—usually two of them: one which is mounted in the tank and one engine-mounted—and fuel injectors. It’s the system through which diesel fuel must be delivered into the combustion chamber in exactly the right amount and under proper pressure.

- Batteries and electrical system: A strong battery must be present to energize the startup motor and at the same time to provide the glow plugs. The relay controls both the timing and duration of operation for glow plugs.

- Air intake system: This ensures that only clean air reaches the engine for proper combustion. Most of the time, when a motor vehicle fails to start, this could be due to a dirty air filter restricting airflow into the engine.

All these components have to work together for a successful engine start. When one of them falters, your engine will refuse to cooperate.

Most Common Diesel Engine Problems Upon Starting

Let’s see the most frequent culprits behind diesel engine starting problems:

Fuel system troubles

- Clogged or dirty fuel filter: Diesel fuel can have impurities pre-existing that will accumulate over some time, therefore clogging the fuel filter. This restricts fuel flow to the engine from occurring, which contributes to hard starting or stalling.

- Air in the fuel system: Air bubbles can prevent fuel delivery to the injectors, which would cause a crank but no start. This will happen quite frequently after you change your fuel filter or if you have a leak in your fuel lines. In this case, you close the system by opening a bleeder screw on the filter or pump and letting some fuel run to bleed all the air out.

- Faulty fuel pump or injectors: Fuel pumps wear out with use, whereas fuel injectors get clogged over time. A weak fuel pump cannot attain the required fuel pressure, while faulty/clogged fuel injectors cannot atomize the fuel appropriately. Symptoms include hard starting, poor engine performance, or black smoke from the exhaust.

Electrical System Problems

- Weak or dead battery: A great amount of current is drawn by a starter motor to crank the engine, and the glow plugs also demand sufficient voltage to enable them to work effectively. In this kind of case, the weak battery will be unable to deliver power as required, leading to slow cranking or no cranking.

- Problems with the glow plugs: Badly worn glow plugs or a faulty relay will cause hard starting, mostly during cold weather. When the glow plugs are not heating up properly, it does not allow the combustion chamber to reach the optimal temperature that a diesel needs for ignition.

- Starter motor malfunction: This is indicated by a clicking sound when turning the ignition key or cranking of the engine slows down. Sometimes, it may not work at all. If this fault is within the starter motor, then it shall be repaired or replaced.

- Faulty wirings: Corrosion, loose connections, or physical damage to the wires can obstruct the flow of electricity to the starter motor, as well as to the glow plugs. Carefully check the wiring and its connections for any damage.

Problems with Engine Compression

- Low compression: Compression is what creates the heat necessary to ignite the diesel fuel. Causes of low compression include worn piston rings, which allow compression pressure to bypass and travel up through the cylinder wall, leaking valves, or a blown head gasket. The symptoms are hard starting, poor performance, and excessive blow-by, an initial indication of more serious problems. Once the condition is diagnosed as being due to low compression using a special tool, checking compression will probably require professional engine repair work.

Other Potential Causes

While the above are the most frequently encountered problems, other possibilities include:

- Low temperatures: Diesel motors are more susceptible to low temperatures. The fuel thickens, and the performance of batteries drops. A block heater, a good battery, and cold-weather starting procedures suggested by the manufacturer can help to some extent.

- Engine problems such as Incorrectly timed valves, a blown cylinder head gasket, or faulty injectors.

- A plugged diesel particulate filter (DPF). These trap emissions, and if they plug, can severely restrict the flow of your vehicle’s exhaust and may cause hard-starting. Be on the lookout for glow-plug warning lights that may indicate problems and have it checked by a mechanic.

- Engine control module (ECM) malfunction: This is your engine’s brain, controlling many diverse functions. Some involve fuel injection and ignition timing. A faulty ECM can cause a host of start-up and performance problems.

Troubleshooting Tips

If your diesel won’t start, the following steps will troubleshoot the issue.

- Safety first: Park on level ground, apply the parking brake and turn off all accessories.

- Preliminary checks:

- Check your fuel gauge. Is there enough fuel in the tank?

- Look for warning lights on the dashboard. Are there any indicators of a problem?

- Inspect the battery terminals for corrosion and clean them if necessary.

- Check under the hood first for obvious leaks or damage.

- Crank the engine: Turn the ignition key and note whether or not the starter motor turns the engine at a normal speed. Check at the tail end of the vehicle for some clues, too, by watching the color of smoke coming out of the exhaust pipe. In addition, look for white smoke, which may indicate a problem with the glow plugs, and black smoke may signal a problem with fuel.

- Systematic elimination:

- Start with the most common problems first. Check for either a bad fuel filter or the existence of a weak battery.

- Check for air in fuel lines and bleed if necessary.

- Check the glow plugs for faulty ones and replace them.

Phoenix Diesel Repair Can Help

Diesel engine starting problems cause many people a lot of frustration. Most problems, however, can be fixed with proper knowledge and an appropriate method. Proper maintenance, paying attention to warning signals, and professional help will keep your diesel in good running condition. But please remember that Phoenix Diesel Repair is always here to help with all your diesel needs. Don’t hesitate to contact us if you have a problem.